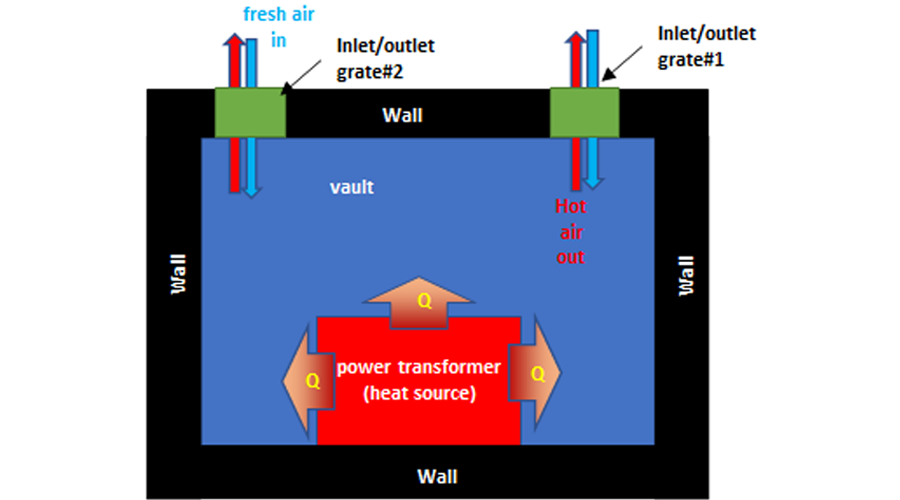

Scenero 1: Traditional Transformer Vault Design with open grates.

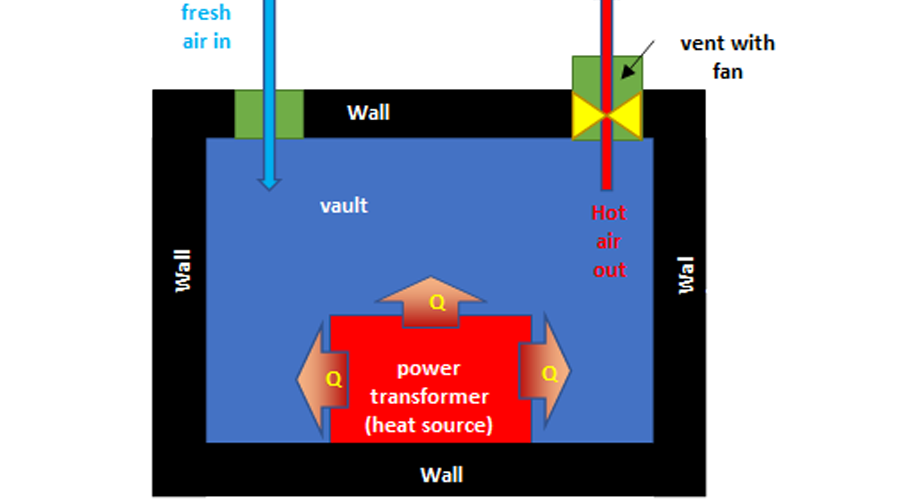

Scenario 2: Transformer Vault with forced Ventilation, no grates.

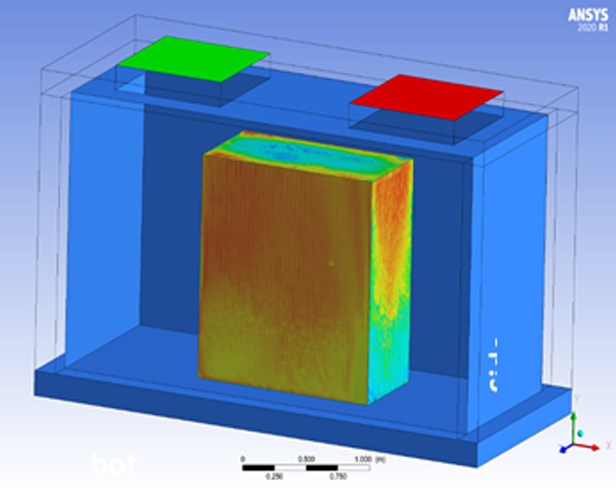

Both scenarios model using Computational Fluid Dynamics (CFD)

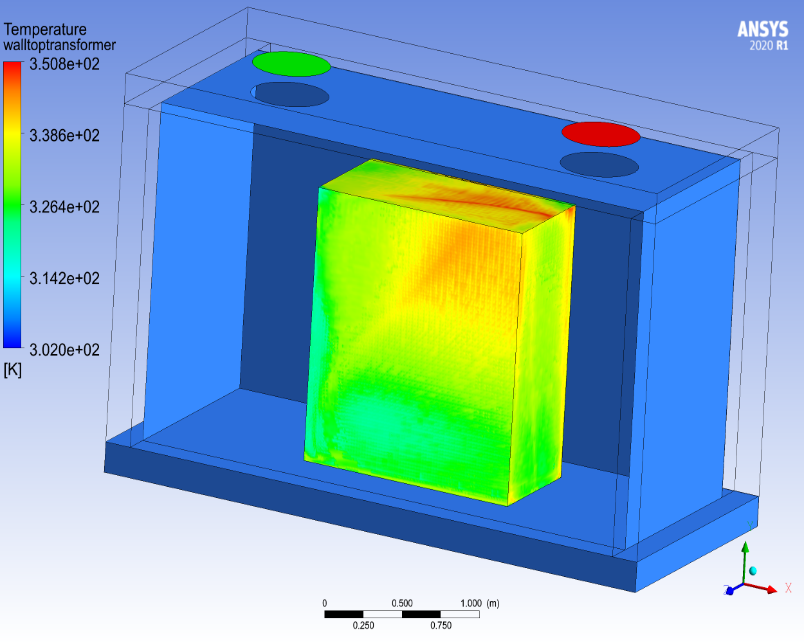

CFD simulation of a 500kVA power transformer installed in a standard 11.5ft L x 4.5ft W x 6.5ft H vault

Scenario 1 – Vault construction with dual grating

Scenario 2 – Vault construction using 2000CFM VaultVent for forced cooling and vault vent intake

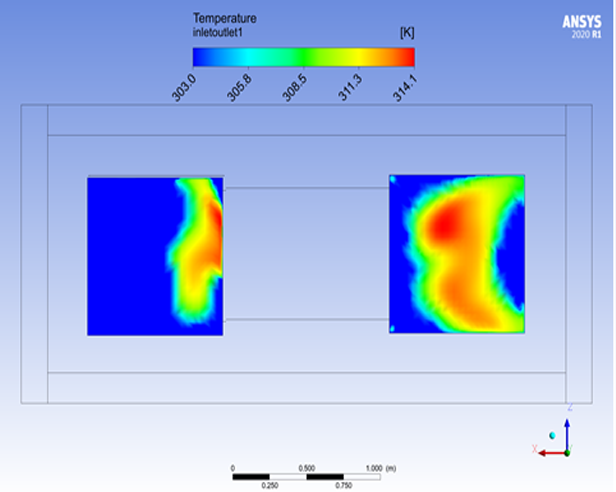

Scenario 1 – Transformer Vault Simulation w metal grates

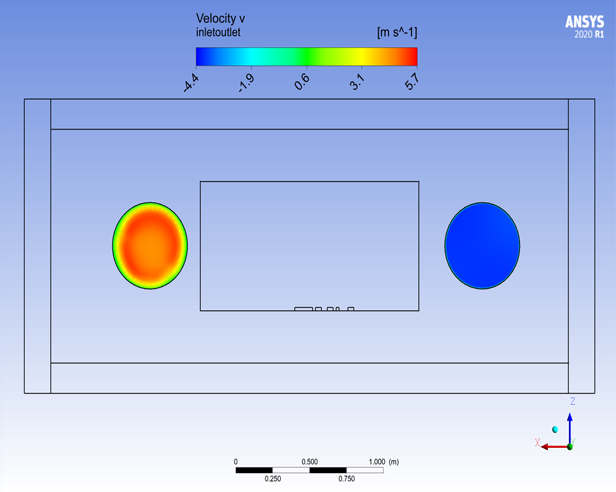

Scenario 1 – Fresh air enters (blue) and hot

air exits (red) provides poor heat transfer

since warm and cooler air flow through same grate with maximum flow rate of 0.15 Kg/s

Scenario 2 –

Vault construction using 2000CFM VaultVent for forced cooling and vault vent intake